Sludge dewatering technologies

In nearly all wastewater treatment technologies, a solid waste/secondary raw material is produced, which contains the original pollutants and, therefore, requires further treatment—neutralization, recovery, etc.

It can be confidently stated that whatever the future holds for these materials—commonly referred to as sludge—their water content must be reduced, if for no other reason than to decrease transportation costs. This reduction occurs during so-called sludge dewatering operations, which aim to reduce the water content and consequently the mass!! These operations are now almost exclusively mechanical processes, with the most common dewatering equipment being the following:

- belt filter press,

- chamber filter press with plastic plates,

- centrifuge,

- screw press.

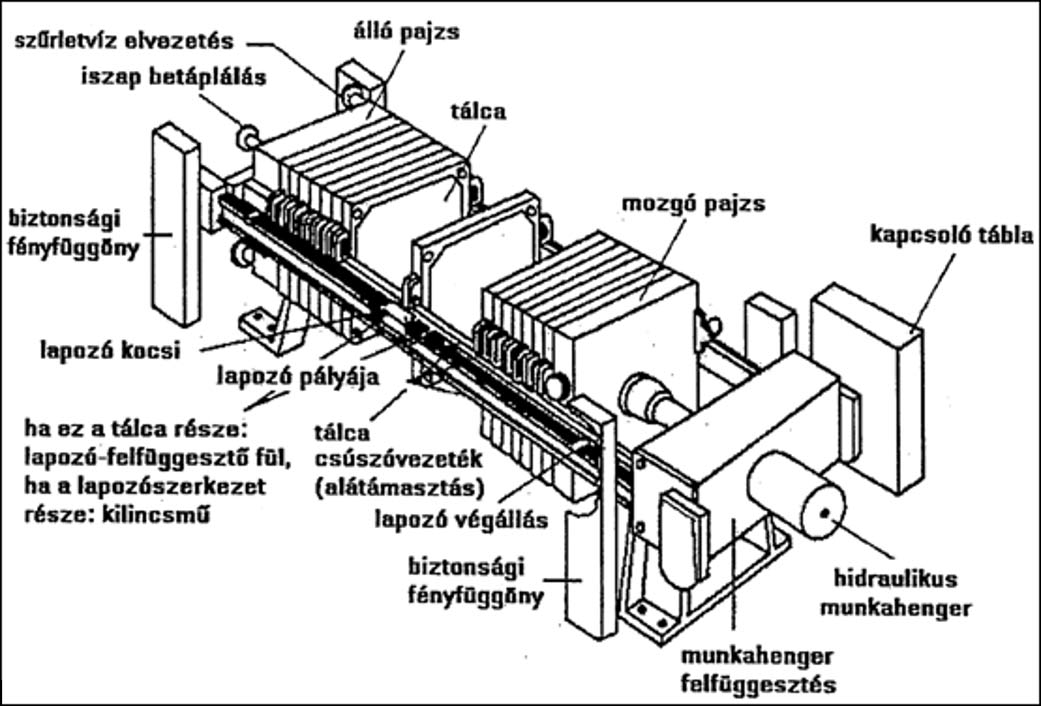

Belt filter presses have become widely used in municipal wastewater treatment plants. The continuous operation mode and the relatively high capacity have made these machines nearly exclusive, despite the fact that they have a high demand for wash water and their complex belt guidance systems practically require continuous operator supervision for operation.

Belt filter press (Blue Sky Co.)

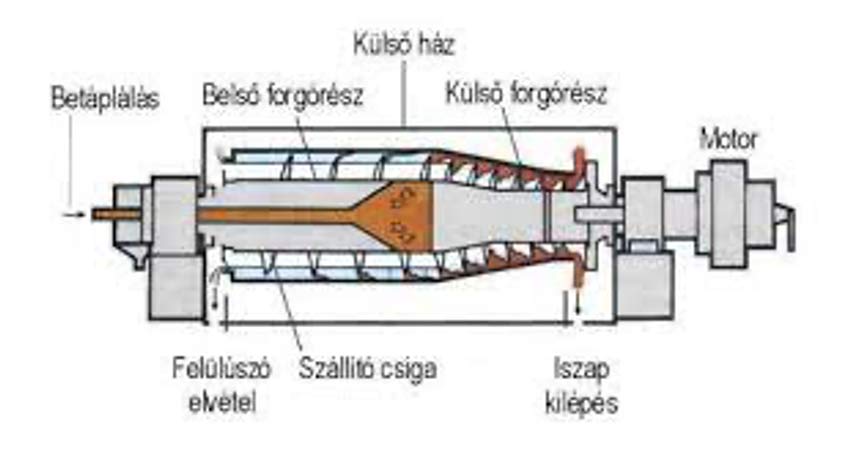

Gradually, the centrifuge has made its way into this field, which is due to the high investment and service costs. These were offset by the higher dry solids content and large capacity.

Sludge Dewatering Centrifuge (BME/Pécs Miklós: Isolation of bioproducts)

In cases of primarily industrial wastewater sludges, where increasing the dry solids content—i.e., reducing the mass—is especially important for the disposal of hazardous waste, the use of chamber filter presses with plastic plates has become widespread. Examples include sludges from galvanizing, paint, and machinery industries. For sludges typically containing metal hydroxides, the highest dry solids content, up to 35-40%, can be achieved using a chamber filter press with plastic plates. However, the equipment operates in batches, and its capacity is limited by the volume of the chamber.

Chamber Filter Press with Plastic Plates (Öllős G.: Szennyvíztisztító telepek üzemeltetése II)

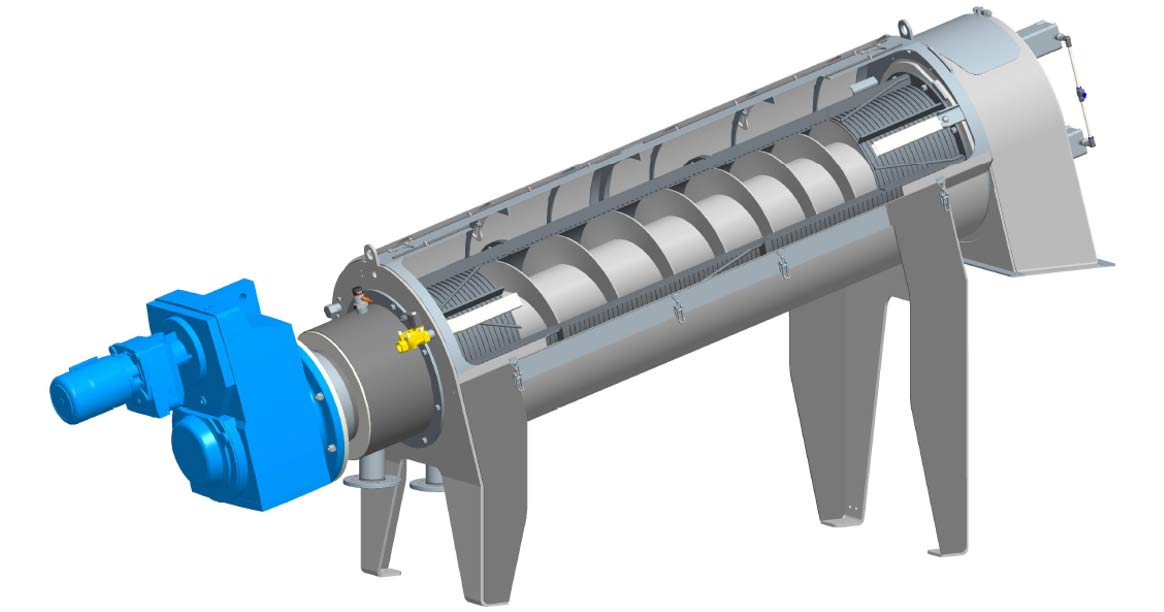

A recent development is the screw sludge press, which fundamentally has the potential to replace belt filters in the municipal market and centrifuges for applications requiring lower capacity. Its operation is simple, it generates no noise pollution, and the service costs are also low.

Screw Sludge Press (HUBER SE)

The table below provides a simplified comparison of the above-mentioned dewatering equipment. From the brief descriptions and comparisons of the sludge dewatering technologies mentioned above, it is clear that there is no such thing as "the best" process. There is, however, an optimal process for a given task! However, this must be selected during a detailed design process, taking into account local technical, economic, human operational, and technological characteristics as design base data!

| Feature | Screw Press | Centrifuge | Belt Filter Press | Chamber Filter Press with Plastic Plates |

| Dewatering Efficiency | Like with Centrifuge | Like with screw Press | 4-6 % smaller than that of the screw press | high |

| Rotational Speed | 0,8 - 1,4 rotation/minute | 2.800 - 3.500 rotation/minute | - | - |

| Noise Level | low | high | low | just pump noise |

| Wear Part Cost | low | high wear on the drum and screw | high wear on the belt | low |

| Lifespan | 15-20 years | 10-15 years | 10-15 years | 15-20 years |

| Filtrate Water Quality | average | dependent on the disc setting | average | susupended solids free |

| Polymer Consumption | average | average | good | good |

| Rinse Water Demand | minimal | with every start and stop | continouosly high | do not require |

| Time Necessary to Reach Operational Status | instant | time consuming | time consuming | instant |

| Daily Maintenance Requirement | short | with every start and stop | requires continouos belt cleaning | short |